As fewer heat is made use of in the course of the drinking water jet chopping approach than most other CNC types, it is often utilized to cut products that would usually have their Qualities modified by warmth. The procedure is usually very specific, and is useful for quite intricate carving and reducing.

Without responses, if errors manifest there's no way for an open loop system to learn. It will eventually therefore continue until possibly you end the machine, or a Restrict change is strike.

A lot of these lathes are just about interchangeable based upon the functions they're able to conduct. When you discovered before, using a turret opens up a wide array of automation opportunities. Also, quite a few far more functions can be performed on just one workbench.

A 4-Axis CNC Lathe introduces an extra axis, generally the C-axis, which lets the spindle to rotate perpendicularly towards the reducing aircraft. This included axis expands the machine’s ability to produce complex designs and styles, offering you far more versatility in CNC lathe machining.

Professional CAD-CAM software may optimize portion structure to use the minimum product attainable. The CAM software checks for almost any glitches, and exports the element to be a G-code file which tells the machine the speed, coordinates, and many different other important elements.

These machines might be Outfitted with 3, 4, or even five axes, offering a lot of chopping capabilities. The sophistication of CNC turning machines allows for generating high-excellent parts with restricted tolerances, building them indispensable in industries that desire precision and efficiency.

CNC turning is often a exact and functional manufacturing technique that may turn your models into actuality. Do you think you're All set to begin?

Depending on these personalized Guidelines within the G-code file, the machine might be programmed for specific speeds, positions, and can switch out tools for various parts of the method to find the best outcomes.

A CNC lathe is really an assembly of intricate components, each taking part in an important function in its operation. Knowledge these components gives you a deeper Perception into how these machines achieve such high amounts of precision and efficiency. In this article’s a breakdown of the key parts:

Swiss lathes run with unbelievably small tolerances at shorter cycle instances than conventional lathes, making them a lovely selection for manufacturing complex parts at larger volumes.

CNC lathes are multipurpose machines able to performing a wide range of functions, Every contributing to the development of Shop now precise and intricate parts:

With about fifteen decades of working experience within the CNC machining marketplace and a skilled group, we offer Value-powerful machining products and services from China. Get yourself a quote for your ongoing or forthcoming assignments nowadays!

one. Run the machine on Trace method. It is possible to operate Every tool route independently, 1 line at any given time to review the tool path movement to the machine to confirm the place of the appliance and when any fixture/vise is in the way in the cutter’s route.

To “pocket” scan an item that contains a shut pocket for example circles or squares, the scan will start off from the top rated front, operate its way inside the pocket, and scan your complete perimeter of the pocket.

Jennifer Grey Then & Now!

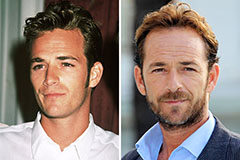

Jennifer Grey Then & Now! Luke Perry Then & Now!

Luke Perry Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!